Product Information

Water-soluble quenching liquid is also called water-soluble quenching agent, water-based quenching liquid, etc. It belongs to the PAG quenching medium. By changing the concentration, it can be made into quenching liquids with different cooling rates from water to oil. It is suitable for overall quenching, induction quenching, carburizing quenching and quenching of aluminum alloys after solid solution heating of various types of workpieces. It can effectively avoid quenching cracks and soft spots, obtain high and uniform hardness and sufficient hardening depth, and greatly reduce quenching deformation.

Product Benefits

Sencro is at the forefront of the country in the research and development and production of water-soluble quenching fluids. The long-term stable performance is the fundamental advantage of Sencro 's water-soluble quenching fluids. It has independently established the aging standard for water-soluble quenching fluids and can provide aging degree detection for water-soluble quenching fluids and aging repair for quenching agents. No blackening, no odor, no bubbling, and no rust are Sencro Industrial Media's commitment to the industry.

Features

1. Replacing water can reduce parts deformation and avoid cracking;

2. Replacing oil can increase the quenching hardness of parts;

3. Parts are easy to clean after quenching and are non-corrosive;

4. Non-toxic, odorless, non-irritating, non-flammable, with stable performance, not easy to age, and will not deteriorate after long-term use:

5. Suitable for most types of steel that require quenching;

6. Widely used in box furnaces, salt bath furnaces, mesh belt furnaces, high and medium frequency induction heating quenching and gas carburizing, carbonitriding direct quenching.

7. Environmental protection, economy and stability.

Physical And Chemical Indicators

Product Model | PH | Operating temperature | Scope of Application | Applicable Furnace Type |

Senco-P65 | 9-11 | 10-50 | Integral quenching of small-sized workpieces such as 35, 45, 35 CrMo and solid solution treatment of aluminum alloys | Mesh belt furnace Pit furnace Pusher furnace Rotary hearth furnace Casting furnace |

Senco-P75 | 9-11 | 10-50 | Integral quenching of medium and large size workpieces such as 40 Cr, 42CrMo, 40Mn2, 35MnB, 40 MnB, 5GrNiMo, 5GrMnMo, etc.; carburizing and quenching of materials such as 20 Cr, 20 CrMo, 20 CrMnMo, 20 CrMnTi, etc. | |

Senco-P85 | 9-11 | 10-50 | Quenching of spring steels such as 60Si2Mn, 60Si2 Cr VA, 55Cr Si2, 50CrVA, 65Mn, etc.; quenching of alloy steels such as 40GrNiMo, 40GrMnMo, etc. | |

Senco-P95 | 8-11 | 10-50 | Surface quenching |

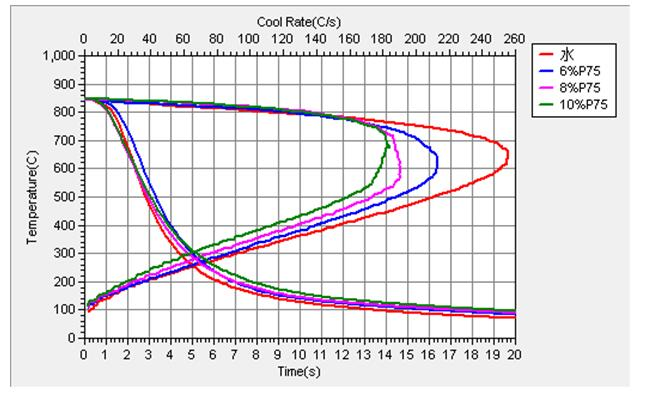

P75 Cooling Speed Comparison Chart At Different Concentrations

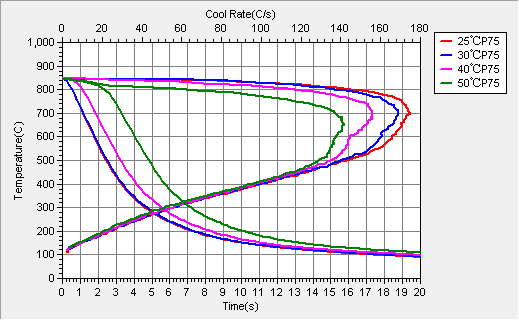

P75 Cooling Speed Comparison Chart At Different Temperatures

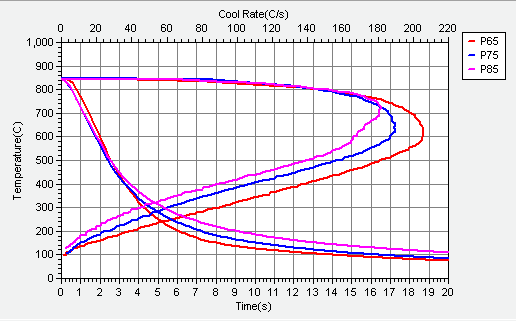

Comparison Of Cooling Speed Of Different Models

Applicable Workpiece

1. It can be used for overall quenching of carbon steel, low alloy steel, carburizing steel and spring steel.

2. Quenching of bars, profiles and steel castings and residual heat quenching of forgings.

3. Overall quenching and surface spray quenching of transmission parts.

4. Quenching of steel leaf springs, spring collets, bolts and nuts.

5. Quenching of clamps, wrenches and other hand tools.

6. Quenching of small workpieces (bicycle parts, chains, etc.) that are heated by continuous furnace carburizing and carbonitriding.

7. Surface quenching of crankshafts, camshafts, pinion shafts, gears, spline shafts, axle pins, chain shafts, saw blades, guide rails and other parts.

8. Quenching of agricultural machinery parts.

9. Quenching of high-strength parts of construction machinery.

10. Solution treatment of aluminum alloys is also particularly applicable.

11. Heat treatment of petroleum equipment.

12. Fire-fighting high-pressure gas cylinders and natural gas tanks.

Packaging And Storage

Sencro quenching agent is packaged in 208L iron barrels, with a net weight of 200KG per barrel; it should be stored indoors and avoid direct sunlight; after use, tighten the cap to keep it sealed.

中文

中文 English

English Deutsch

Deutsch Français

Français Русский

Русский Español

Español