Product Introduction

Vacuum quenching oil is a quenching oil specially used for vacuum furnaces. It has a short distillation range, low saturated vapor pressure, strong anti-vaporization ability, good thermal stability, and fast cooling speed. The cooling speed of A is higher than that of B. A is particularly suitable for quenching and tempering of carburized workpieces, and can also be used as a cooling oil for solution treatment of austenitic stainless steel. B is a milder cooling vacuum oil, similar to graded quenching oil. Users can choose according to the quenching requirements of the workpiece. The operating temperature is 20℃-80℃, and it is mainly used for workpieces quenched after vacuum heating. It can obtain good brightness, high and uniform quenching hardness and small quenching deformation.

Product Model

Name | Model | Flash point (COC)℃ | Kinematic viscosity @40℃ ( MM² /S) | Moisture | Thermal oxidation stability viscosity ratio> | Maximum cooling rate (℃/S) | Applicable temperature (℃) |

Vacuum quenching oil | Senco-O90A | 215 | 25-35 | trace | 1.25 | 90-95 | 50-100 |

Senco-O90B | 220 | 50-60 | trace | 1.25 | 85-90 | 50-100 |

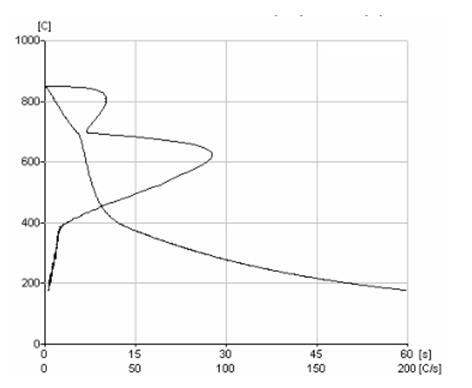

Cooling Curve

Scope Of Application

(1) Vacuum quenching materials for mold steel, including: Cr12, Cr12MoV, H13, 6542, W18Cr4V.

(2) Thin and small parts that are easy to harden.

(3) High-alloy materials with good hardenability, including (bearing steel, tool steel, high-speed steel).

中文

中文 English

English Deutsch

Deutsch Français

Français Русский

Русский Español

Español